Pentastar Engines: Repairs and Maintenance

We are not responsible for the veracity or completeness of this information.

Cylinder head failures (to mid-2013)

In 2012, dealers started to report that some V6 engines had cylinder head failures; the main issue seems to have been overheating of the #2 cylinder’s valve seats. The problem made itself known through the “check engine” light, and did not cause accidents or stalling.

In 2012, dealers started to report that some V6 engines had cylinder head failures; the main issue seems to have been overheating of the #2 cylinder’s valve seats. The problem made itself known through the “check engine” light, and did not cause accidents or stalling.

A fix (hardened valve guides and seats) was engineered and entered production in June. It now appears that a number of 2013 model-year cars and trucks were also affected, indicating perhaps a second change.

Most vehicles with this problem appear to be Jeep Wranglers; a service bulletin was issued for Wranglers built before January 24, 2012 (MDH 0124XX) to prevent “false positive” check-engine lights.

A build date of 2062 (the 206th day of 2012) stamped on the cylinder head shows that it is one of the newer types. The part numbers of the new heads are RL141353AC or higher (left side) and RL141352AD (right side). Update: Some 2013 model year vehicles may have the old heads.

Chrysler has extended the warranty on the left cylinder heads of Pentastar engines for model years 2011 and 2012, and some vehicles from the 2013 model year. Warranty bulletin D-14-12, dated June 10, 2014, tells dealers which vehicles are covered — for ten years or 150,000 miles, whichever comes first.

Early cam phasing

On the forums, one master technicians wrote in 2012: “[The main issue we’ve seen] is the exhaust cam phasers on the early 2011 releases. All it did was set a DTC [check engine light], no performance issue. I have heard of a couple failures at other dealers but in the grand scale of things its been very reliable so far.”

Oil filters

Chrysler quietly changed the oil filters and cap O-rings used on the Pentastar V6 engines from 2011-13’s part number 68109834AA to 68191349AA on 2014 models. The change, which Andy told us affected all Pentastar V6 engines, may have coincided with changes to the oil cooler; however, it might be more likely that it was done to reduce confusion and inventories, since the VM V6 diesel engine used by Chrysler also saw a redesign of the filter and cap O-rings, to the same part number as the gasoline V6. This means that dealers can stock a single filter-and-gasket kit for all Grand Cherokee V6 engines, diesel and gasoline alike — unless, of course, they are from the 2011 to 2013 model years. Using the wrong part will cause an oil leak.

Miscellaneous notes

The Pentastar V6 continues the Chrysler tradition of not using mass airflow sensors; Chrysler is unusual in never having used MAF sensors, instead continuing to use MAP sensors, aided by computer algorithms. The cost is extra development time and extra testing, but the benefit is being able to use a lower cost, often easier to diagnose sensor.

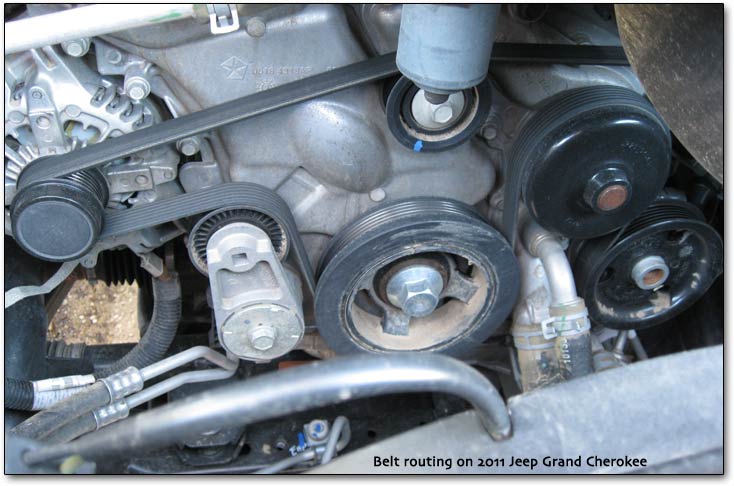

The serpentine belt must be very carefully routed; on the early models currently being produced, the water pump is driven off the back of the belt, so an incorrect routing will result in the pump going backwards. Later models use electrohydraulic pumps, mounted in a different location, with a new belt routing, and full electric steering is expected to replace even this.

Spark plug changes

- Remove the ignition coil (each plug has its own coil)

- Spray compressed air into the cylinder head opening, to help keep dirt out of the combustion chamber.

- Being very careful because the spark plug tubes are very thin, and any damage can cause oil leaks, remove the spark plug from the head using a high quality thin-wall socket with a rubber or foam insert to grip the plug.

Timing cover, head covers, and water pump

- Disconnect the battery ground cable, and drain the cooling system

- Remove the upper radiator hose and thermostat housing; the heater core return and lower radiator hoses from the water pump; and the heater core supply hose from the coolant outlet.

- Remove the electric vacuum pump.

- Remove the bolt and reposition the heater core supply tube.

- Remove the accessory drive belt, tensioner, and pulley.

- Remove the power steering pump pulley and crank vibration damper.

- The head covers can now be removed, along with the upper and lower oil pans.

- The timing cover is attached with three M10 bolts, one M8 bolt, and 23 M6 bolts. Once these are removed, the timing cover can be removed using the seven pry points.

- If the coolant outlet housing and/or water pump need to be replaced, remove the M6 bolts holding them on (four each).

Chrysler cautions against using inappropriate fluids or materials to clean the engine gasket surfaces, recommending only isopropyl alcohol with wood or plastic scrapers to remove residual sealant from the mating surfaces. The coolant outlet housing gasket and water pump gasket should both be replaced.